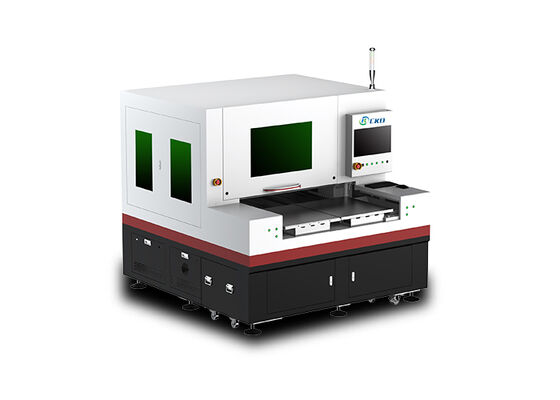

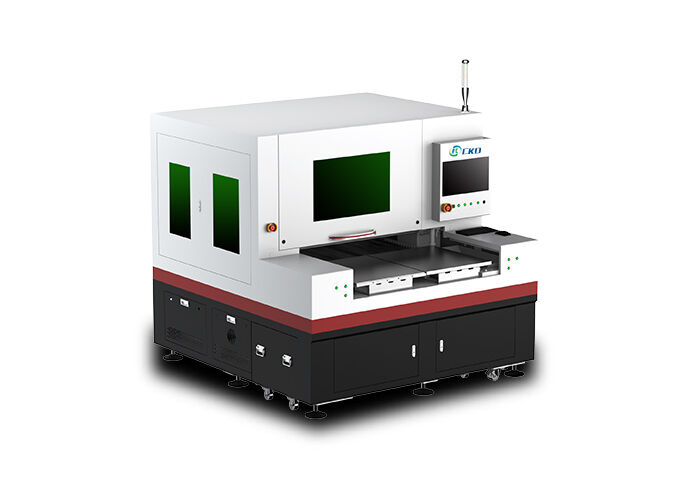

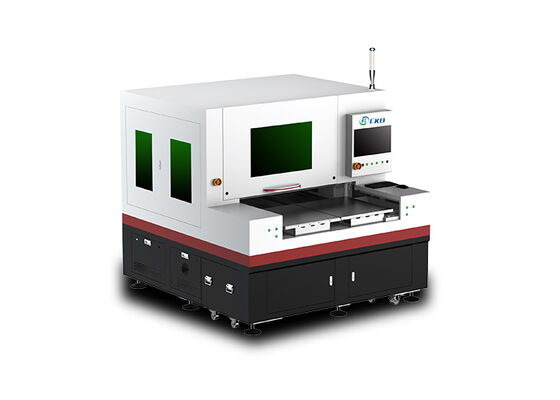

Mesin Pemotong Kaca Laser yang memberikan kinerja energi dan persyaratan perawatan rendah untuk tugas pemrosesan kaca berkelanjutan. Keakuratan ±0.01mm

-

Berat3500kg

-

Memisahkan frekuensi denyut nadi laser1-100kHz

-

Merek panduan linierTpi

-

Frekuensi kerja50Hz/60Hz

-

Konsumsi EnergiStandby Power adalah sekitar 500W, dan konsumsi daya rata -rata selama pemotongan adalah 2.5kW. Efis

-

Memisahkan kekuatan sumber laser150W (Opsi: 250W/350W)

-

Memotong presisi± 0,01mm

-

Apakah cncYa

-

Jenis pendinginanPendingin air

-

Lingkungan operasiSekitar 26 derajat Celcius

-

Akurasi pemotongan± 0,1 mm

-

Berat MesinSekitar 150kg

-

Metode pemotonganPemotongan laser

-

Kecepatan pemotonganKecepatan tinggi

-

Konsumsi Daya≤12KW

-

Kehidupan LayananUmur panjang

-

Nama ProdukMesin pemotong kaca laser

-

Modus pendinginanPendinginan Udara

-

Ketebalan pemotongan0.2-10mm

-

Sistem pengaturanSistem Kontrol Cnc

-

Dimensi keseluruhan4500mm*2500mm*1500mm

-

Ketebalan pengeboran< 19mm

-

Ukuran kerja610*700mm x 2

-

Tempat asalTiongkok

-

Nama merekCKD

-

SertifikasiISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

HargaNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Mesin Pemotong Kaca Laser yang memberikan kinerja energi dan persyaratan perawatan rendah untuk tugas pemrosesan kaca berkelanjutan. Keakuratan ±0.01mm

Deskripsi produk:

Perangkat ini adalah perangkat untuk pemotongan kaca yang efisien dengan laser energi tinggi, di mana pemotongan adalah untuk pengolahan profil,dan laser-assisted CO2 cracking yang digunakan untuk mencapai pemotongan dan retakan kaca.

Cocok untuk memotong profil kaca dari berbagai spesifikasi dan bentuk, menyediakan layanan yang disesuaikan sesuai dengan kebutuhan pelanggan yang berbeda, memenuhi persyaratan pemotongan berbagai kaca

![]()

Parameter teknis:

| Jenis Produk | Mesin pemotong serat laser, Mesin pemotong kaca berwarna, Mesin pemotong kaca meja tunggal |

| Opsi yang dapat disesuaikan | Opsi khusus tersedia untuk ukuran meja, kekuatan laser (hingga 500W), dan kepala pemotong khusus (seperti untuk pemotongan melengkung atau tingkat mikro) untuk memenuhi kebutuhan khusus |

| Berat badan | 3500kg |

| Minimal Cutting Burr | ≤ 5 μm |

| Percepatan | 1G |

| Sistem pendingin | Pendinginan Air |

| Garansi dan Layanan | Dilengkapi dengan garansi 2 tahun yang mencakup komponen utama seperti sumber laser dan sistem kontrol. |

| Pembagian Daya Sumber Laser | 150W (pilihan: 250W/350W) |

| Lebar Pulsa | < 10ps |

| Keakuratan Pemotongan | ± 0,01mm |

| Frekuensi denyut nadi | 1Hz - 1000kHz |

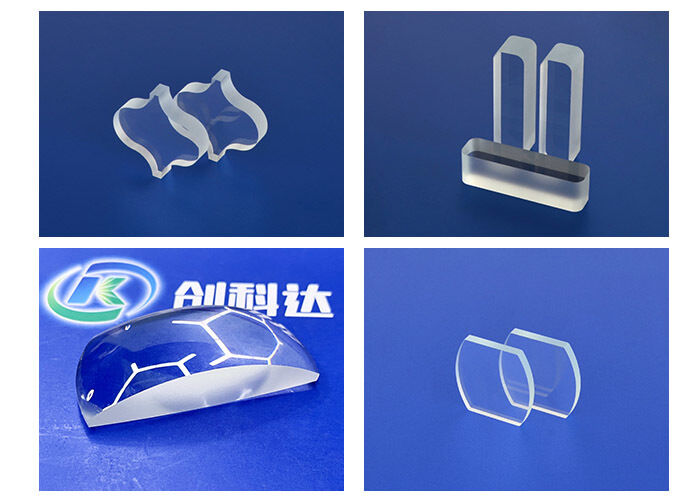

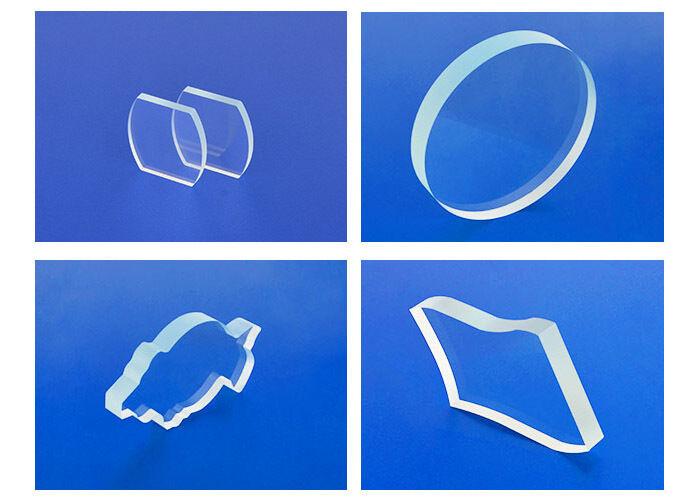

Samlpe:

Dapat memproses "kaca ultra-jelas, kaca putih biasa, kaca silikat bor tinggi, kaca batu kuarsa", dll, penutup ponsel, penutup kaca mobil, penutup kaca kamera, dll, penutup safir ponsel,Tutup kamera safir, pita cahaya safir, kaca K9, pemotongan film filter, pemotongan reflektor, dll. Kaca optik.

![]()

Pengantar perusahaan:

Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. didirikan pada tahun 2010.Ini adalah produsen peralatan laser ultrafast dan otomatisasi penyedia solusi manufaktur cerdas baru yang mengintegrasikan R & DSetelah lebih dari sepuluh tahun budidaya dan akumulasi yang mendalam, perusahaan telah mengumpulkan lebih dari 70 paten, lulus sertifikasi CE,1S09001 sertifikasi sistem manajemen mutu, dan Sertifikasi Sistem Manajemen Kekayaan Intelektual. Ini adalah perusahaan teknologi tinggi nasional dan perusahaan profesional, halus, khusus, dan inovasi Shenzhen.

Perusahaan ini memiliki bengkel logam lembaran, bengkel mesin, bengkel perakitan, dan bengkel pengembangan proses dan debugging, yang mencakup R & D, Produksi, Pengujian, Penjualan & layanan purna jual.

Hingga saat ini, perusahaan memiliki tim R & D yang kuat yang telah terlibat dalam desain struktur laser dan teknologi aplikasi laser selama bertahun-tahun.perusahaan telah mencapai inovasi dan terobosan dalam teknologi produk di bidang seperti ultra cepat laser cutting, pengeboran laser, perbaikan layar TFT-LCD dengan laser, penyegelan dan penghapusan plastik semikonduktor, penggilingan berlian, pengelasan laser, dan penandaan laser.Terutama dalam pengolahan bahan keras dan rapuh seperti kaca dan keramik, perbaikan TFT-LCD, penyegelan dan penghapusan plastik semikonduktor, serta penggilingan berlian dan manufaktur cerdas baru otomatis lainnya, kami menyediakan pelanggan dengan biaya rendah, berkualitas tinggi,dan solusi efisiensi tinggi,memberikan kontribusi kepada pelanggan dengan nilai tambah,inovasi,dan pengembangan.

![]()

![]()

Kemasan dan Pengiriman:

Kemasan produk:

Mesin Pemotong Kaca Laser dikemas dengan hati-hati menggunakan bahan berkualitas tinggi dan tahan lama untuk memastikan perlindungan maksimum selama transportasi.Mesin pertama-tama ditutupi dengan busa anti-statis dan bungkus gelembung untuk mencegah kerusakan dari kejut atau getaran. Kemudian ia ditempatkan dengan aman di dalam peti kayu yang kokoh yang diperkuat dengan bracket logam untuk stabilitas tambahan.Semua bagian dan aksesori yang longgar dikemas secara terpisah dalam kotak berlabel di dalam petiKemasan dirancang untuk tahan kelembaban dan mencakup instruksi penanganan yang jelas dan label peringatan untuk memastikan transportasi yang aman.

Pengiriman:

Kami menawarkan pilihan pengiriman yang dapat diandalkan untuk mengirimkan Mesin Pemotong Kaca Laser dengan aman ke depan pintu Anda. Mesin dikirim melalui operator kargo tepercaya dengan pelacakan yang tersedia untuk semua pengiriman.Tergantung pada tujuan, kami menyediakan angkutan udara, angkutan laut, atau transportasi darat untuk memastikan pengiriman tepat waktu. tim logistik kami mengkoordinasikan proses pengiriman, termasuk bea cukai dan dokumentasi,Untuk mengurangi keterlambatanSetelah tiba, pelanggan disarankan untuk memeriksa kemasan dan mesin dengan hati-hati dan melaporkan kerusakan segera.

![]()